HullOpenings

Hull Openings & Closures

Overview

All exterior doors, hatches, vents, ports and windows should be watertight (not weather tight), located on the centreline, lockable and fitted with alarms. Watertight means no water will pass through in either direction if the water has a head. AAmpere (amp), SI unit of electrical current head is a column of water.

ISO 112216 gives specifications for boats under 24 mMetre, SI unit of length. Category A closures, for boats built for offshore, is designed for Force 8 winds and significant wave heights of 4 m (just over 13 ftFoot) or more but excluding hurricanes, etc. Category BBeam is also designed for Force 8 winds but significant wave heights only up to 4 m. Category C closures are for boats used inshore.

Make sure all deckhouse openings are watertight. Deckhouse windows should be positioned so they are not submerged with the boat heeled 60 degrees. Any openings that could be submerged at 90 degrees heel should also be watertight. In particular, don’t compromise on cockpit doors. There are some very nice patio doors for cockpits that are only weather tight. These will not serve you well when following waves are breaking over the cockpit, in the event you are facing waves the wrong way around.

Deck hatches and door sills should be at least 12-in off the deck. Portholes should be at least 20-in above the load waterline. Portlights and windows should be inset for two reasons: they are architecturally cool, and they ensure conformance to ISO 112216 no matter what slope the sides of the hull.

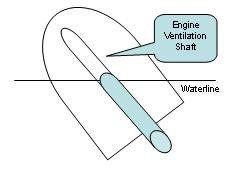

Water and fuel intakes should be at least 4-in off the deck to prevent ingress of dirt. Openings for the engine room ventilation should be at least 36-in off the deck. (Air intakes on the side of the hull are susceptible to letting water in.) Extend the intakes down close to the engine room floor. In the event of capsizing, this will keep the inside opening above the waterline so that water doesn’t siphon in. The air intake should have a shutter to cut off air in case of an engine room fire. Fit all vents, dorades and other openings with metal rodent screens.

Doors

All external doors should be watertight and lockable. Sliding doors are safer and better than doors that latch back and can swing free. The door from the pilothouse to salon, and interior companionways from the main deck to below deck should also be watertight and lockable. Need we say doors in watertight bulkheads should also be watertight.

Windows

Windows with overhangs reduce significantly the amount of air-conditioning needed; curtains and blinds are less effective. Ideally overhangs would provide shade from southern sun angles in summer and expose windows in winter for maximum heat gain.

Window Protection

Deadlights and shutters protect portlights and windows from storms, knock-downs and invasion. Of course, situational awareness plays a big role. Shutters are of no use if they’re open when you need them closed.

There are various types of portlight. Generally a deadlight is a fixed portlight that does not open, but it can also describe a portlight that has a metal cover on the inside that can be locked down. In this latter case, the portlight can be fixed or open-able.

Storm shutters should be on all offshore boats. Storm shutters are designed to protect windows from storm waves and flying objects in either a hurricane or a knock-down. In a knock-down, all kinds of things will be breaking lose and smashing against the windows. Keeping the windows intact is essential if there is to be any hope of the boat recovering. For knock-down protection on windows, mild steel is the best choice because it won't bend and break the glass. Windows required for navigating will need a viewing slit in the shutter, or shutters made from Polycarbonate (Lexan® or Makrolon®).[1] Polycarbonate has very high impact resistance and does not break easily.

Storm shutters that can be locked also provide security in rough ports, and when everyone is away from the boat. Piracy is on the increase, and global warming will cause other troubles.

When moored and a hurricane threatens, simple protection can be made of plywood, Plexiglas, aluminium and steel, depending on your requirement. Major factors are availability, cost and ease of installation. Effective shutters can be made from 3/4-in Mahogany plywood that is varnished. If the windows are inset, it is better to inset plywood shutters, fixing them in place with 4-in barrel bolts every two feet. Insetting them will prevent the wind from tearing them off. Shutters can also be attached with channels, studs or threaded inserts.

Window Glass

Any glazing materials should be (in order of descending strength) chemically reinforced glass (CGCentre of gravity), tempered glass (TG), poly(methyl)methacrylate (PMMA), or polycarbonate (PC). Laminated glass is also available but may discolour over time. Glass should be thick enough, at least 19 mm, to withstand water pressure in a capsize.

It’sSecond unlikely that you will find theses types of glass with low-E. Low-E glass has a coating that reflects long-wave radiant energy. This helps keep in the heat in winter. Thermochromic glass will also be available soon. It has a thin film made out of a material called vanadium dioxide. On cold days the film allows all sunlight in. On hot days, at a temperature of 25 C, the film blocks short-wave infrared rays, which are responsible for generating heat. Super-hydrophilic coatings are also available to control condensation; but so far their life span is only one year.

Hull Openings

Other hull openings are required for water intakes and outlets, propeller, thrusters and stabilizers, and instruments such as depth sounder, sonar, and logs, etc.

A sea chest is a hull opening, say 15-inches square, which centralises water connections. (A sea chest is also a sailor’s footlocker.) The opening has a rectangular chest built up inside the hull to above the water line. It is fitted with a removable top to allow inspecting and clearing the external connections inside the chest. Its purpose is to supply a single-source for all of the intake water for engines, air conditioners, raw-water wash down, etc. Usually when a boat needs another source for water, you cut yet another hole in the bottom, with inherent issues including fouling, brass fittings, barnacles, etc. With the sea chest, these issues are localized.

There isn’t much information available about sea chests. Only Defever seems to use them. Advocates claim that, as a side benefit, so much water is forced through the sea chest opening that barnacles have to work a lot harder to attach. It’s unclear what effect turbulence inside the chest has on water circulation to the boat’s systems. It would seem reasonable to separate intakes and outlets as much as possible inside the box, or in separate chests. Exhaust headers and intake manifolds on racing engines might offer some design clues.

The other main opening is for the propeller shaft. Traditionally, ships have used a stuffing box to seal the opening around the shaft. This is literally a box stuffed with marine grease. Stuffing boxes always leak a bit into the bilge. They’re fitted with a grease nipple and, every so often, you stuff them up. More modern approaches exist in the form of seals. They tend to wear more on the shaft. A few can be replaced without removing the shaft.