HVACIntegration

HVACHeating, ventilation, air conditioning Integrated Design

Summary

This article works through the considerations in designing heating, ventilation and air-conditioning (HVAC) systems for year-round living on a 50-foot boat. Some of the concepts and calculations can also be applied to your next house.

The design is not optimal. When the furnace fails in the coldest weather there is a heating shortfall of 21,560 BTUBritish Thermal Unit or 6 kilowatts (kWKiloWatt, 1000 watts).

Design Considerations

Description

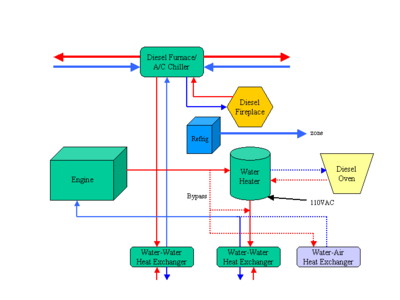

The HVAC system uses a blend of loosely coupled systems to provide maximum energy efficiency and redundancy for a year-round live-aboard. Fresh-air ventilation uses small zone-based air vents but this makes humidity control difficult. The heating and cooling systems use a shared circulating-water distribution system to minimise bulkhead pass-throughs. Heating is by a diesel furnace with backup from a diesel fireplace. Cooling is by a chiller with keel cooler, with backup from the cold-plate refrigeration system. Hot water is heated by the engine, the diesel oven, a solar collector or ACAlternating current elements using shore power or the house bank.

For completeness in understanding the trade-offs made, the engine cooling system, hot water and refrigeration and watermaker are also shown. Details are described further below.

Design Goal

The design goal is a year-round live-aboard in north-eastern North America. Some of the design considerations are:

* One single fuel type on board * Minimize AC loads * Minimize sound transmission * Pre-heat water for the water maker * Minimize energy usage * Maximize efficiency * Minimize dependencies * Provide redundancy

The requirement for a single fuel type effectively eliminates propane heating in favour of diesel. Diesel is anyway much safer. It is also more efficient, providing around 140,000 BTU per gallon (galGallon), compared to 91,000 for propane.

Distribution System

The first major issue is whether to use forced air or circulating water to distribute heating and cooling. Memories of cold radiators in grade school in the dead of a Canadian winter, and the comfort of humidity control with forced air in modern homes predisposed the solution to forced air. Over time, the solution changed several times. In the end, circulating water was chosen to:

* Reduce the size of ducts in the insulated space * Eliminate a path for airborne noise and dirt from the engine room * Reduce the general level of air-borne dust * Eliminate the need for a cold-air return * Minimise openings in watertight bulkheads * Deliver a more even heat by reducing stratification * Eliminate cold drafts on start-up

Like electric heating, hot-water heating is very dry. This is offset by ventilation, which introduces fresh air. AAmpere (amp), SI unit of electrical current programmable thermostat is located in the forward passageway. In each living area, opening/closing individual radiators will control temperature manually.

Backup Heat

In addition, to provide backup in the case of failure in a severe cold spell, a diesel bulkhead fireplace in the salon, such as the Kabola [1] Old English Diesel Room Heater or the Harworth Bubble [2] is also plumbed into the distribution system. Other types of bulkhead heater are available from Dickinson Marine [3], Refleks [4] and Sigmar [5].Initially a fireplace was desired for lifestyle reasons, but as the design evolved it became a backup system. The Dickinson Bristol Diesel Cook Stove in the galley can also heat the forward accommodation, but it is not part of the main distribution system.

Towel Rails

The main distribution system also routes through the towel rails in various compartments. These are switched out of the circulating water system in summer and heated with AC elements.

Related Systems

Engine Cooling

Under way, engine coolant circulates through the hot water tank, and hence to a water-water heat exchanger with keel cooler. Another feature of this design is that raw seawater is not circulated through the engine. There is a bypass circuit around the water heater that closes thermostatically when the heater is at temperature.

In winter if the boat is out of the water, the engine may have to be run to charge the batteries. In this case, an optional water-air radiator in the engine room provides engine cooling.

Hot Water

Hot water is heated in several ways. In port in summer, the water is heated by standard electrical elements operating off the alternating current (AC) system. In winter, it is heated by the water jacket on the diesel oven. If the oven is not in use, and there is no other source of heat, the hot water tank defaults to the electrical elements.

Use an anti-scald, balanced-pressure shower valve (not a tempering valve!) on the showers to regulate the water to 120 Fahrenheit (°Fdegree Fahrenheit) 48.8 Celsius (°Cdegree Celsius, SI unit of temperature). This will avoid scalding people, and reduce water consumption. Bathers will be able to mix the water faster to a comfortable temperature.

Refrigeration

Additional cooling for one zone is provided by a cold-plate refrigeration system. A high-efficiency cold-plate design for the refrigeration will reduce AC loads, while not imposing a continuous direct current (DCDirect current) load. Excess capacity may be used for air conditioning.

Watermaker

For cold water expeditions, the water intake to the watermaker should be preheated.

HVAC Scenarios

With this integrated design, the following scenarios apply:

Fireplace in use:

Central furnace is turned down

Oven in use:

Central furnace is turned down Central hot water AC is turned off

Main engine in use:

Central hot water AC is turned off

Central furnace fails:

Fireplace and oven provide central and space heat

Central furnace and distribution system fail:

Fireplace and oven provide space heat

Shore AC power fails:

Oven provides hot water DC-AC inverter provides electricity to hot water elements

Control Zones

For heating, ventilation and air-conditioning distribution and control purposes, the boat is divided into the zones in the below table. With a KKelvin, SI unit of thermodynamic temperature=1 (see Heating Calculation), the boat requires approx. 37,810 BTU/hBritish Thermal Units per hour of heating. The main diesel furnace supplies this, sufficient for the coldest weather.

| HVAC Zones | ||||

|---|---|---|---|---|

| Description | Zone | Distribution | Air Conditioning BTU (K=1) |

Heating BTU (K=1) |

| Forward cabin | 1 | 44%percent | 24,349 | 16,637 |

| Aft cabin | 2 | 17% | 9,408 | 6,428 |

| Pilothouse | 3 | 18% | 9.961 | 6,806 |

| Salon | 4 | 21% | 11,621 | 7,940 |

| Engine room | 5 | - | - | ? |

But what happens in an emergency? In the event the furnace fails, the Bristol Pacific model diesel stove in the galley can provide 6,500-16,250 BTU to heat the forward accommodation. At the lower heat setting it could maintain a temperature differential of 21 °C, while the higher one maintains the design differential requirement of 55 °C in the forward compartment.

At the lower setting, water pipes, etc., are protected down to -20 °C, a not infrequent winter temperature, which is why the design requirement is the higher 55 °C differential. Because the galley stove alone cannot heat the whole boat in the event of a furnace failure, additional heat has to be supplied by the diesel fireplace in the salon. A fireplace such as the Bubble produces only 3.5 kW (11,946 BTU), good for a 17 °C differential overall. So it will only heat the pilothouse and salon, not the aft cabin.

Therefore in an emergency in the coldest weather we have a heating shortfall of 21,560 BTU (6 kW). This is not critical above deck in the salon and pilothouse, since there are no water pipes there. But it is critical in the aft head.

Finally, some heating has to be provided to the engine room to keep water tanks and pipes from freezing. Obviously some further development is required in the design of the back-up heating. Increasing the output of the diesel stove is not a good option, as this would tend to make it less useful as a cook stove. Perhaps the Bubble should be re-located to the aft cabin, but this negates its lifestyle purpose. More practical solutions are to shut off the water to the aft head and run the engine to keep the engine room warm. Another solution is to have an aft engineroom and a contiguous forward accommodation space.

Related Pages

Calculating Heating Requirements

Calculating Ventilation Requirements

Calculating Air Conditioning Requirements