DieselEngines

Diesel Engines

The engine of choice for a boat is a marine diesel from a manufacturer such as: Caterpillar, Cummins, Detroit Diesel, [cwww.deutz.de/ Deutz], Lugger, Man, Perkins, Vetus, Volvo Penta, Westerbeke, Yanmar, ZF-Marine. Diesels are more efficient per gallon of fuel than a gasoline engine and much much safer. The only significant alternatives on the horizon are fuel cells. BoatDiesel.Com has a wealth of information on diesel engines, transmissions and propellers.

Invented by Rudolf Diesel circa 1898, diesel engines are pressure ignited. They use the familiar four-stroke Otto Cycle of intake-compression-combustion-exhaust.[1] Unlike a gasoline engine, which uses spark plugs to ignite a compressed mixture of air and fuel, diesel engines use the heat of compression to ignite the fuel-air mixture. Diesels use very high compression to do this. Like all modern engines, diesels use fuel injectors to spray fuel into the combustion chamber at the precise best moment.

AAmpere (amp), SI unit of electrical current good diesel engine will produce about 20 hphorsepower per gallon/hour compared to 12 hp per gallon/hour for a gasoline engine.[2] Put another way, a 300-hp diesel will consume about 15 gallons an hour while a similar gasoline engine will consume about 25 gallons.

Diesels are very reliable and robust, but they are only as good as the fuel system. Most troubles with diesel engines stem from the fuel system, and can be prevented through maintenance and a high-quality filtering system. The engine should also be fitted with a starter button, bypassing the one on the bridge; and a dry sump and drip pan.

Fuel System

Diesel fuel deteriorates when stored. (So does gasoline, for that matter.) Diesel fuel has a shelf life of approximately 100 days. The chief causes of deterioration are oxidation, condensation, micro organisms, corrosion and sedimentation.

Oxygen combines with the hydrocarbon molecules, forming particulates, water and gum. Condensation inside the tank deposits more water. Bacteria and fungi collect and grow at this water-fuel interface in the fuel tank. They eat diesel fuel and give off more water and acids. Corrosion in the fuel tank releases metal into the fuel, accelerating the oxidizing process.

Water, microbial growth, and stray voltages can cause corrosion in steel tanks. In addition, fuel can be contaminated with water and sediments on delivery; and air can be drawn into fuel lines where fuel is leaking.

Sediments, moisture, and air can block fuel filters or disrupt an injector. Sediments such as clay and sand originate in the crude oil; others from the sludge that precipitates as the fuel deteriorates.

Good practice is to keep tanks full to avoid condensation, and minimize mixing fuel from different sources, as this can reduce the stability of the fuel. Condensation on the outside of a tank is a good sign! It means the dew point inside the tank will not be low enough for condensation inside.

Religiously maintain filters, injectors and fuel pumps, and inspect fuel lines for leaks. It also helps to use a petroleum solvent such as Pri-DDisplacement, Depth of ship or Run-Right[3][4], but avoid the regular use of biocides, as they are corrosive. Note also that diesel substitutes like bio-diesel, made from vegetable oils, animal fats, and recycled cooking oils, introduce new sets of problems.

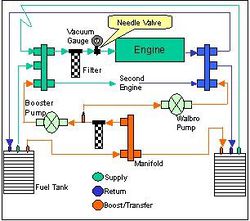

A high-quality filtering system consists of at least three micron filters, water separator and a circulating fuel system to polish fuel. The term polishing means cleaning the fuel. A polishing system should have a high flow rate to turn over a tank quickly and also because most filters are designed internally to work better with a higher flow. Depth-type filters are better than edge-type filters.

Avoid using a day tank. It is better to constantly polish the fuel in the main tanks. A day tank holds enough fuel for a day’sSecond run, but if you don’t use all of the fuel, the day tank becomes just another fuel tank with the attendant problems. Fuel should be polished at least three times a week; and always returned to the tank of origin. A top-outlet fuel tank eliminates the risk of dumping fuel if a line breaks.

Tanks should not have open cross-connections as this will reduce stability. As the boat heels, fluid will run to the lower side, adding weight. Consider a fuel-shut-off valve outside the engine room in case of fire.

Lubrication

Finally, to protect the engine from lack of lubrication during heeling, the engine should have a dry sump. Wet sumps are the most common. In a wet-sump engine, the lubricating oil, usually several quarts, is contained in a sump (oil) pan bolted underneath the engine block. During heeling, the oil runs to the side and, in the worst case, can starve the engine of oil, causing damage to the bearings. Oil can also slosh onto the lower cylinder walls, reducing power.

In a dry-sump engine, the oil is kept in an external tank. The tank can be as large as you want. Typically, there are two oil pumps, one for pressurising the oil galleries, another for scavenging the oil from the sump.

While this provides protection during stormy weather, when the boat is being tossed around, it doesn’t provide full engine protection in a knockdown. The engine won’t suffer oil starvation in a knockdown, but it can still be flooded by oil if the scavenging pickup sucks air.

An ignition shut-down switch activated by oil pressure is also advisable. Such a switch (e.ggram., a universal voltage switch) should also be fitted with an alarm.

Cold Weather Starting

Consider adding a block heater to the engine, controlled by a thermostat, for starting in cold weather.

References

- ↑ How Engines Work, http://www.keveney.com/Engines.html

- ↑ Fuel Horsepower, Tony Athens, http://boatdiesel.com/Articles/

- ↑ Power Research Inc., http://www.priproducts.com/

- ↑ . C.A.T. Products, Inc., http://www.run-rite.com/

- ↑ Fuel Filters, Tony Athens, http://boatdiesel.com/Articles/