AcousticalIsolation

Acoustical Isolation

Isolation and Well Being

Noise reduction through acoustical isolation is necessary for well being at all times. It is extremely important in a live-aboard boat to keep noise within a comfortable range. We experience sound in terms of a frequency range measured in Hertz (HzHertz, SI unit of frequency) and air pressure measured in decibels (dBDecibel). The ear has a very wide non-linear response to the intensity of sound, so each 10 dB increase is ten times louder. Thus a 20 dB increase is 100 times more intense. Duration is also important. Constant noise over 85 dB will damage hearing.

For reference, the ambient noise level in most homes is 30-35 dB. Car interiors are around 40 dB. AAmpere (amp), SI unit of electrical current normal conversation is around 60 dB. A diesel engine room is around 125 dB (wear ear protectors!}. A jet plane taking off is around 140 dB. For bedrooms, to get a good restful sleep, the World Health Organization recommends 30 dB with no single noise event exceeding 45 dB.

Eliminate Source

A good strategy is to eliminate sound at its source, especially in the engine room. This reduces the cost of acoustical insulation elsewhere. Noise attenuation of 100 dB is feasible. Some areas for consideration are:

- Engine and exhaust-system mounts to decouple engine noise from structural members

- Engine enclosures for generators with heat-resistant sound-dampening materials

- Exhaust mufflers

- Air intake baffles

- Flanking noise via holes in bulkheads and water, plumbing and HVAC distribution systems

- Floor, ceiling and walls of the engine room

- Bulkheads and doors in living spaces

- Isolating all wall panels from structural boat walls

In addition to the noise of combustion, there are several considerations in designing acoustical-isolation systems for an engine room. These are drive-train vibration, especially from the propeller, the peak frequencies generated by large noise generators such as the engine, and the range of noise to which the ear is most sensitive.

Complicating matters a bit, every engine and engine room is a unique case. However, noise radiation from the crank case and oil sump is typically 500 to 1,000 Hz. Engine block vibrations run below 1,250 Hz while gear noises run above 2,000 Hz.

The human ear responds to sounds in the range of 20 Hz to 20 kHzKiloHertz but is most sensitive in the 1,000-5,000 Hz band with a peak around 4,000 Hz. The auditory canal alone has a closed-tube resonance of 2,000-5,000 Hz.

For a production boat it’sSecond feasible to do a spectrum analysis and design suitable sound attenuation and test it. For a bespoke boat this is unlikely to be feasible. Thus a good cost-effective approach is to focus on reducing sound transmission, in a target range for engine noise such as 1,000-2,500 Hz (wavelengths of 13.5 to 5.4 in or 34.3 to 13.72 cmCentimetre).

Methods of Isolation

Acoustical isolation works by converting sound waves into heat that is then dissipated. Some methods of isolation are:

- Reflecting sound waves

- Dampening sound waves

- Converting sound waves to heat energy

- Decoupling surfaces

Reflecting sound within a room causes sound to lose energy, reducing the amount of sound radiation outside the room. A common method of achieving this is to have reflective material on the outside surface of insulation. However the room shape and size can also have a major impact. The best shape for noise cancellation is a cube. The next best is a room where all dimensions are a multiple of the height, e.ggram., a room that is 7 x 14 x 14 ftFoot.

Dampening sound is achieved by absorbing it in insulation. The depth of insulation should be calculated to absorb the desired wavelengths (see above, 6-14 in for engine noise). Cabins can be quietened with hollow walls and doors filled with acoustic dense fibre matting (DFMDense fibre matting) mineral wool or an aerogel sheet[1] or use structural insulated panels (SIPStructural insulation panel). Aerogel is also an excellent thermal insulator, with a value of around R22 per inch.

DFM mineral wool is non-flammable and chemically inert. A random arrangement of fibres ensures no water penetration in any direction. It is rot proof, non-hygroscopic and will not encourage the growth of fungi, moulds or bacteria.

Sound waves can be converted to heat energy by adding mass to surfaces. Vibrating a mass absorbs more of the sound energy. Mass can be added by marine-grade plywood panels or lead surfaces on insulation. Medium-density fiberboard (MDFMedium-density fiberboard) is not as hard as plywood and can sag under heavy weight. MDF doesn't handle moisture very well, either.

Decoupling is achieved by using viscoelastic dampers between surfaces, and air gaps to prevent direct conduction. Air gaps need especial attention because they can resonate, especially at the lower frequency (1000-400 Hz) wavelengths of 13.50 to 33.76 in (34.3-85.75 cm). Resonance will transfer acoustical energy across the gap. An ideal space of 100-200 mm (3.9-7.9 in) is recommended in building construction.[2]Isolating the Engine Room

Design an engine room entrance that has a double door. The inside door should be watertight (with a view port) and the outside one should be air tight. The space in-between would make a good place to hang ear protectors and other safety equipment. Both doors should have significant solid mass to absorb sound.

With a saloon above the engine room, sound can be attenuated in the design of the sole and the engine-room ceiling below that.

For acoustic isolation in the sole build up a layered floor consisting of (starting at the bottom) a sub-sole, viscoelastic glue as a damper, an underlayment of acoustic mat made of dense rubber (similar to the mat used in horse stalls), then cement board and flooring.

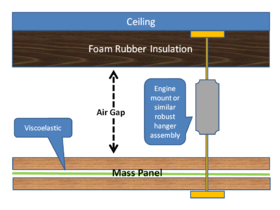

In the engine room an ideal ceiling would provide attachment points for a drop ceiling. This would require spring hangers (or even rubber engine mounts) capable of withstanding high accelerations of mass to avoid detaching the ceiling in a capsize. The attachment points should be 100-200mm long. Attach two layers of non-combustible panels bound with viscoelastic glue. Several marine-approved panel materials are available.

Where the composite panel meets the walls, prevent flanking noise leaking through using a flexible acoustic strip such as neoprene.

On the room side, apply to the composite panel composite insulation such as lead-fibreglass with the fibreglass rated at, say, R13. Since we are dealing with wavelengths of, say, 5 to 14 in, the thickness of the insulation should be in the same range.

An alternate arrangement is shown in the image.

A ceiling of this type, combining mass, decoupling, resilient mounts and insulation is capable of attenuating noise 60-75 dB over 1000-5000 Hz.[3]

If there is ductwork originating in the engine room, use round lined ductwork (insulated on the inside). Round ducts transfer less sound than square ones. In the engine room coat the exterior of the duct with a viscoelastic material, and cover it with a soffit to prevent exposure to direct sound. Consider a 90 or 180 degree bend to force sound to interact with the duct liner. Where possible, use serpentine lengths of lined flex duct to create a more complex path for sound.

Similar techniques could be used on the bulkheads. For example, in the engine room use a viscoelastic glue to stick a non-combustible panel on the bulkhead, then attach the composite insulation. In the living space on the other side attach furring strips using neoprene rubber. If more isolation is needed incorporate rubber mat or more insulation. Always leave an air gap to prevent conduction.

Make sure materials are fire-resistive according to marine codes. A fire in the engine room can transfer by conduction to other spaces through steel bulkheads.

Some Cautions

Finally, some cautions. Some complex isolation schemes were described above for the purpose of illustration, but you should keep the design as simple and robust as possible. For example:

- The performance of two mass panels isolated by a viscoelastic glue can exceed that of a limp mass, such as lead-loaded composite insulation. It may be feasible to use just ~R13 fibreglass with the mass panels.

- A triple mass-panel sandwich alone that consists of a mass panel glued (viscoelastic) to either side of a bulkhead can achieve attenuations of 60 dB.[4]

- Test. Sound meters with a range of 35-130 dB can be rented (or use an iPhone app):

- Start with a basic installation of isolation in the engine room. Run the engine and use a sound meter to measure the noise in adjacent cabin areas. Upgrade the isolation to reach your sound goal.

- Or, build a small test box with a logging sound meter inside. Add test isolation externally. Evaluate the performance of your choices by suspending the test box in the engine room and running the engine.

Links

http://www.audioholics.com/room-acoustics/a-guide-to-sound-isolation-and-noise-control

http://www.audiology.org/sites/default/files/journal/JAAA_09_06_02.pdf

References

- ↑ Aspen Aerogel Inc., http://www.aerogel.com/

- ↑ http://www.build.com.au/window-acoustics-and-noise-control

- ↑ The Green Glue Company, http://www.greengluecompany.com

- ↑ ibid